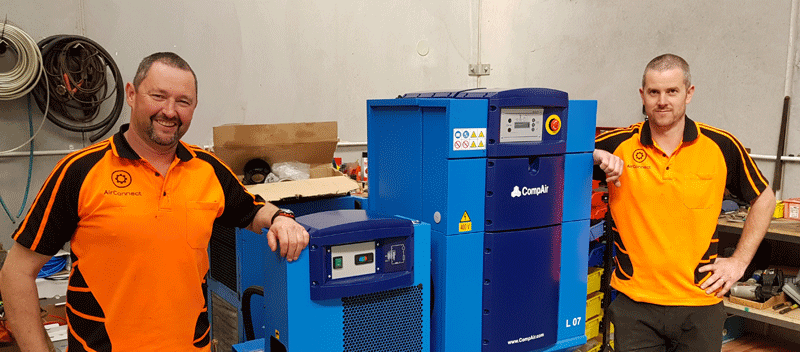

Steve and Raymond offer professional air compressor sales and servicing.

Pneumatic tools can be found anywhere from industrial or construction sites to Kiwi backyards that need some DIY. They come in all different shapes and sizes, used by woodworkers, mechanics, contractors and homeowners for minor repairs and improvements to major undertakings. They have great benefits, from being safe and portable to being easy to operate.

But above all, air tools make any kind of handyman work faster even for the less experienced. An air powered nail gun, for example, will drive in far more nails in a much shorter time than anyone could achieve by hand, making the job far more efficient and saving you valuable time.

However, unlike manual tools and equipment, air tools and the air compressors they run off for power require regular service and maintenance in order to function properly. If neglected, they not only lose their efficiency, they can also pose serious health and safety risks if parts become lose or damaged. Failure to service your pneumatic machinery leads to deterioration because residual oil and water build up on the inside.

Furthermore, pneumatic tools generally have a recommended pressure range they should be operated in. Anything lower or higher can lead to a variety of problems which in the long run will cost a fortune to fix. Let alone the hassle of dealing with unhappy customers or major projects gone wrong.

For all your compressor and air tool servicing needs, AirConnect is your best contact anywhere between Warkworth and Kaitaia. The qualified team offers extensive knowledge and expertise when it comes to pneumatic tools, making sure your equipment is serviced, repaired and returned to you in a timely manner. They also specialise in spare parts and accessories for a wide range of tools, so no matter what, the downtime for your business is kept to a minimum.

To keep your grease guns, staplers, compressors and more running smoothly, a regular maintenance schedule is essential. Check-ups can help prevent serious damage and avoid unnecessary costs. Service should take place at least annually, more often depending on usage, and include replacing oil, oil filter, oil separator, intake filter & line filters. This will help keep your tools working at optimum performance. There is nothing worse than having to shut down an entire job due to faulty equipment, when an annual service could have picked up minor issues along the way that were faster, easier and cheaper to fix than replacing an entire air-tool.

If you feel your pneumatic tools or air compressors could do with an overhaul, contact AirConnect today for a free quote. They are locally owned and operated, putting customers’ needs first. Should your equipment need a repair, AirConnect stocks a whole range of parts and accessories from dowel pins to throttle valves and o-rings. Otherwise, the friendly team will help you source whatever you need as soon as possible.

And to make it easier to remember when your next service is due, AirConnect can put you on a maintenance schedule with intervals that work around your business. This ensures maximum productivity with minimum downtime so you can focus on the more important aspects of your business.